SEIKO Watches

In this, the final installment of our three-part series in partnership with Grand Seiko, we take a look at the many hands that work together to make a finished Grand Seiko Spring Drive wristwatch. Grand Seiko is famous for showing enormous attention to detail in every part of the watch, from the hands, to the dial, to the assembly of the movement, to the hand-polishing of the cases of each watch, and here you'll get a look at both the processes and the people behind them.

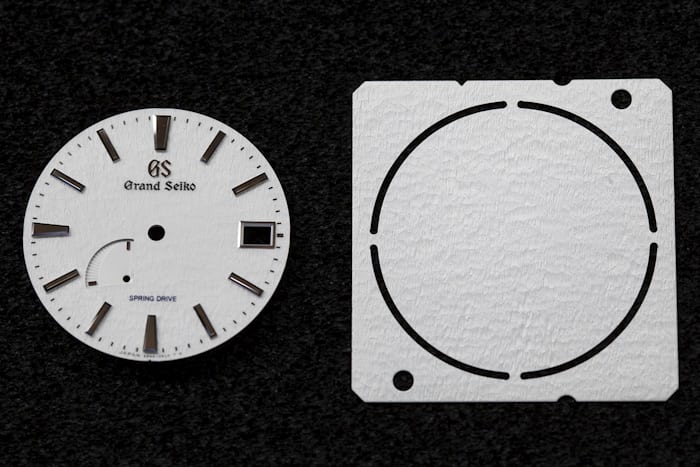

In progress: the dial for the Spring Drive "Snowflake."

One of the most truly remarkable aspects of Grand Seiko manufacturing is the degree to which many of the techniques involved are still largely manual and artisanal, and in this video you'll see some of these techniques first hand. You'll see indexes for the dial being diamond cut on a special tool by a craftsman who examines each one for the right degree of polish and reflectivity. The blued steel seconds hands are heat-blued individually; a process that requires close attention to achieve the correct shade of cornflower blue. Dial manufacturing for many of the most popular Grand Seiko dials, including the famous "Snowflake" and radially brushed dials, involves many steps and a high degree of very skilled, hands-on work as well; the rotary brush for making the dial is made by hand, with the hair-fine wires meticulously trimmed by hand.

Components for the Grand Seiko Spring Drive Chronograph.

Although it takes many hands to make a Grand Seiko watch, and although watchmaking is inherently and necessarily a collective enterprise, there is one aspect of a Grand Seiko watch which is in the hands of a single individual: the assembly of the movement. In this installment, you'll see a watchmaker assembling one of the most complicated Grand Seikos: the Spring Drive Chronograph, which takes advantage of Spring Drive technology to provide an elapsed-time measuring tool with Spring Drive's unique, smoothly gliding seconds hand. Assembly of a Spring Drive chronograph – a vertical clutch, column wheel self-winding chronograph which, like other Spring Drive watches, requires very high precision watchmaking – is done by a single watchmaker.

We hope you'll enjoy this final installment, and we also hope that you'll be pleasantly surprised and interested to see just how much care, and careful hand-work, goes into every Grand Seiko watch – just as we were during our time in Japan at the Shinshu Watch Studio in Shiojiri, where all Spring Drive Grand Seiko watches come to life.

0 comments:

Post a Comment